42 Reasons Why Quality Matters

In the Hitchhiker’s Guide to the Galaxy, Zaphod Beeblebrox wore his Joo Janta 200 Super-Chromatic Peril Sensitive Sunglasses, which were specifically designed to help people develop a relaxed attitude to danger. At the first hint of trouble, they turn totally black and thus prevent the wearer from seeing anything that might alarm them.

Whilst ignorance is one approach to continuous improvement and business success, is it really a viable alternative?

In this article, I’ll explore the secrets to survival and glory, with no special sunglasses required.

Don’t Panic: Why Quality Is the Ultimate Answer (and Continuous Improvement the Question)

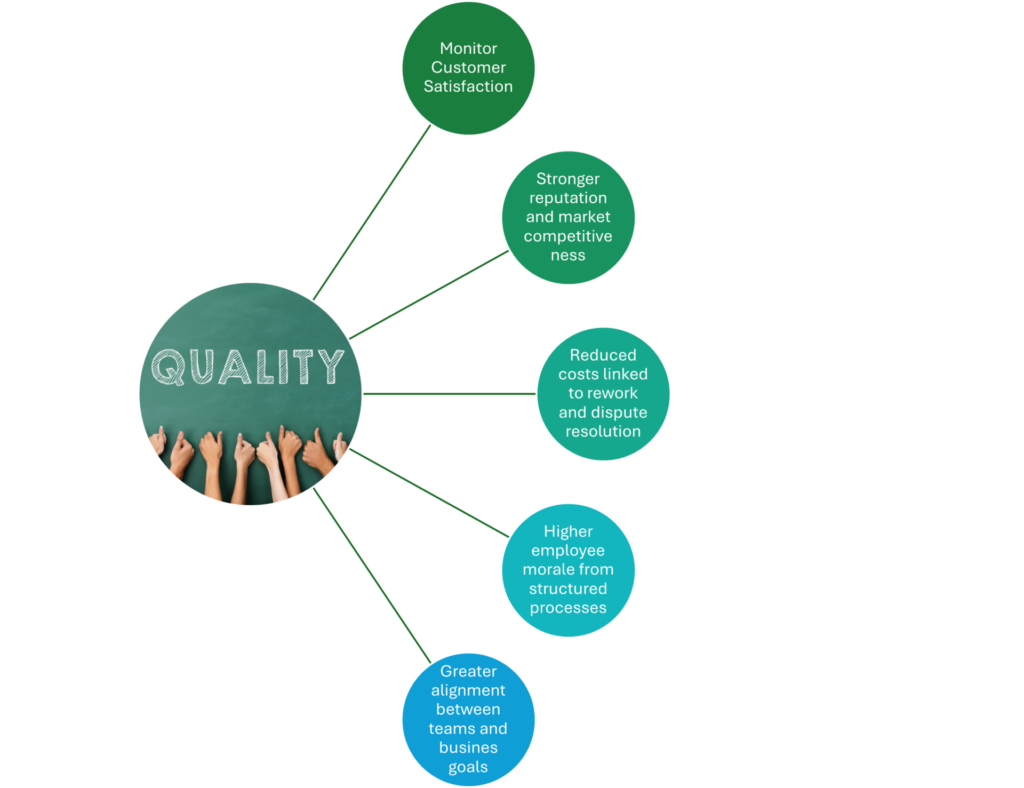

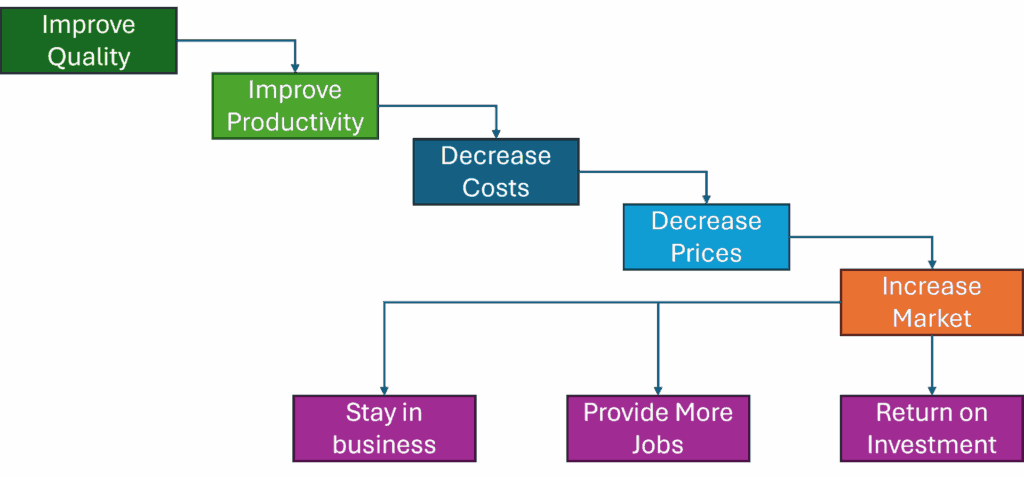

Quality management systems (QMS) are often misunderstood as compliance exercises or administrative burdens. In reality, a well-designed QMS is the engine that drives improvement, innovation, and long-term business success.

Research[1] consistently shows that organisations with strong quality practices outperform those without them. Leadership commitment, employee engagement, data-driven decision making, and customer focus form the link between quality and both operational and financial performance.

Studies from Australia and around the world confirm that frameworks such as ISO 9001 improve productivity and efficiency. They also reduce rework, strengthen customer satisfaction, and improve profitability. It costs less to get things right the first time, and that principle remains at the heart of every quality program.

How do the elements of a sound quality management system lead to these outcomes? What are the secrets?

Customer Satisfaction and Business Success

I’m probably not telling you anything new here: customer satisfaction is key to business success.

A satisfied customer is not only a repeat buyer but also an advocate who strengthens the brand’s reputation through loyalty and positive word of mouth. Monitoring satisfaction levels provides a direct line of insight into whether a lab’s services truly meet expectations. Feedback often highlights the small gaps that internal audits or data might overlook. When feedback is collected consistently and acted upon, it becomes a powerful mechanism for improvement and innovation. This ongoing dialogue ensures that the organisation remains aligned with what customers genuinely value.

A satisfied customer is not only a repeat buyer but also an advocate who strengthens the brand’s reputation through loyalty and positive word of mouth. Monitoring satisfaction levels provides a direct line of insight into whether a lab’s services truly meet expectations. Feedback often highlights the small gaps that internal audits or data might overlook. When feedback is collected consistently and acted upon, it becomes a powerful mechanism for improvement and innovation. This ongoing dialogue ensures that the organisation remains aligned with what customers genuinely value.

Good customer experience is the visible outcome of strong quality management. It depends on reliability, consistency, and care at every stage of the customer journey, from first contact to long after delivery.

In The Hitchhiker’s Guide to the Galaxy, travellers are advised to always know where their towel is: a small act of preparedness that makes the journey smoother. In business, the equivalent is knowing where the customer stands. Labs that listen, adapt, and anticipate customer needs show that quality is more than a system. It is a mindset that builds trust, strengthens performance, and secures lasting success.

Reputation and Resilience

Quality also determines reputation. Once reputation is lost, it is difficult to rebuild. Product recalls, service failures, and compliance breaches often arise from weak quality control or inconsistent processes. Customers associate these failures with the entire organisation, not just a single incident.

In a world where reputations travel faster than light (or at least faster than a bad tweet), consistent quality builds the trust that sustains a business. Labs that cut corners may improve short-term profits, but the long-term cost of recalls, rework, and reputational damage is far greater.

By contrast, companies known for reliability, open communication, and effective problem-solving build trust that endures. These businesses understand that quality is not defined by the absence of problems. It is defined by the presence of systems that identify and correct issues quickly and transparently.

Learning Through the Plan-Do-Study-Act Cycle

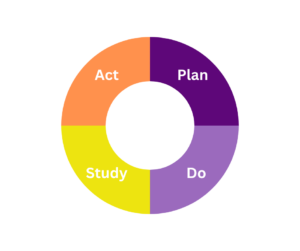

At the heart of every successful quality management system lies the Plan-Do-Study-Act (PDSA) cycle. This simple yet powerful model provides a structured way for organisations to learn, adapt, and improve continuously. Many people know about it, but few implement it properly.

The cycle begins with planning, where a change or an improvement initiative is defined. It might be a new idea for doing things better or addressing a problem. This stage also involves formulating a theory, including identifying the root cause if it is to deal with a problem, defining success metrics and developing the steps to be taken to implement the idea or improvement initiative

The doing stage involves implementing the test, changes, or planned actions on a small scale, allowing teams to test ideas in a controlled environment.

Studying the results of the test, a change or improvement initiative is the next stage. This means we focus on analysing data and feedback to determine what worked and what did not.

Finally, acting involves adopting and standardising successful changes and integrating them into routine practice. It could also be that the planned change or actions for improvement are abandoned if the evidence shows it did not work. In this case, you need to run through the cycle again.

The strength of the PDSA cycle is that it replaces assumption with evidence. By testing and reflecting before rolling out changes widely, labs prevent recurring errors and reduce the need for rework.

This disciplined approach helps identify root causes early, rather than reacting to symptoms later. The result is fewer process failures, improved communication, and a significant reduction in customer complaints or disputes. Problems are resolved before they escalate, and learning becomes part of everyday operations rather than an occasional event.

In the words of The Hitchhiker’s Guide to the Galaxy, the most reassuring phrase in the universe is still “Don’t Panic.” The PDSA cycle embodies that philosophy. It provides a calm, logical framework for solving problems without resorting to quick fixes or blame. Each iteration of the cycle builds knowledge, strengthens confidence, and improves consistency. Over time, this disciplined repetition becomes a habit of excellence, creating organisations that are not only more efficient but also more trusted by customers and staff alike.

In the words of The Hitchhiker’s Guide to the Galaxy, the most reassuring phrase in the universe is still “Don’t Panic.” The PDSA cycle embodies that philosophy. It provides a calm, logical framework for solving problems without resorting to quick fixes or blame. Each iteration of the cycle builds knowledge, strengthens confidence, and improves consistency. Over time, this disciplined repetition becomes a habit of excellence, creating organisations that are not only more efficient but also more trusted by customers and staff alike.

Employee Morale and the Human Side of Quality

A well-designed quality management system gives employees more than checklists and procedures; it gives them clarity and confidence.

When processes are clearly defined and consistently applied, people know what is expected of them and how their work contributes to the organisation’s goals. This structure reduces confusion and frustration, creating a sense of stability and purpose.

Employees who can rely on sound processes spend less time correcting errors and more time improving outcomes. Training, communication, and participation in problem-solving strengthen engagement and pride in workmanship. In short, good systems empower people to succeed rather than constrain them.

High morale is not a by-product of quality management; it is one of its essential outcomes.

High morale is not a by-product of quality management; it is one of its essential outcomes.

Motivated employees are more attentive to detail, more willing to share ideas, and more committed to customer satisfaction. Their enthusiasm becomes visible to clients and partners, creating a positive feedback loop between staff engagement and business reputation.

Labs with engaged teams experience lower turnover, better collaboration, and greater resilience in the face of challenges. As The Hitchhiker’s Guide to the Galaxy reminds us, it helps to “know where your towel is.” In quality terms, this means being equipped, confident, and ready for anything; the mindset of teams who take pride in doing things right the first time and who drive sustainable business success.

Leadership commitment is essential to going beyond Compliance

A quality system reaches its full value when it becomes part of how people think and work, not just what they record in a manual. It is like a good towel, both versatile and indispensable. When quality is embedded in organisational culture through shared accountability and open feedback, improvement becomes instinctive. And who sets the organisational culture? Organisational Leaders.

A good quality culture is one where employees are empowered to identify issues early, managers make decisions based on evidence rather than assumptions and customers experience reliability and consistency at every point of contact.

When quality is treated as bureaucracy rather than a management philosophy, performance and trust decline. Words about commitment to quality mean little if leadership decisions favour speed or cost over doing the job correctly. Employees notice this inconsistency and begin to view quality as something to work around instead of something to uphold.

The best organisations avoid this trap. They integrate quality into their DNA so that improvement becomes instinctive, not imposed. Employees feel ownership; data drives refinement; leadership connects purpose to performance. Each small cycle of improvement, plan- do- study- act, becomes a micro-journey toward excellence.

The Takeaway

Quality management isn’t the bureaucratic paperwork monster some fear. It is not about achieving perfection. It is about learning faster, improving continually, and performing better.

A robust QMS helps a lab concentrate on what matters most: delivering consistent value to customers, improving processes each day, and building a culture where excellence is shared by everyone. In an uncertain and competitive world, that commitment to quality provides one of the most reliable paths to long-term success.

Like the Hitchhiker’s Guide itself, a good QMS reminds us that progress depends on curiosity, courage, and the willingness to ask better questions.

Download this article here.

Remember, you don’t have to do this alone!

Do you need help in asking the right questions, improving your lab’s processes, and building culture? Well, that’s what we do!

At MAS Management Systems, we help labs make quality practical, purposeful, and profitable. Get in touch today to discover how better systems can create better results for your lab. Call Maree at 0411 540 709, or email maree@masmanagementsystems.com.au.

[1] Relationships between quality management, innovation and performance: A literature systematic review, Maríano García-Fernández, Enrique Claver-Cortés, Juan José Tarí, European Research on Management and Business Economics, 28 (1) January–April 2022.