A trio of quality thinkers

Anyone who has ever been involved in quality or project management would have heard the names Deming, Juran and Crosby.

Anyone who has ever been involved in quality or project management would have heard the names Deming, Juran and Crosby.

Their contributions have had long lasting ramifications and made us all think differently about what quality is, what it means and how to achieve it.

Over the coming months, we’ll be running a series of articles about quality. Therefore, it seems fitting to start from the beginning. Let’s run through a brief examination of the visions and philosophies of three thought leaders.

William Edwards Deming

“You do not have to do this: survival is not compulsory”

Dr Deming was an American scholar, professor, author, engineer, and consultant. Because of his belief in continual improvement, he developed a set of transformational theories and teachings that changed the way we think about quality, management, and leadership.

He’s probably best known for his innovative work with Japanese industry, where his input to their post-World War II transformation was credited with their emergence as a world economic power. In the late 1980s, Deming’s methods revitalised such businesses as Ford, Toyota, Xerox, and Sony.

His idea was that the manufacturing process should be viewed as a seamless whole rather than a system made up of distinctly different and unrelated parts. His focus was on improving the quality of the product while reducing costs and providing customer satisfaction.

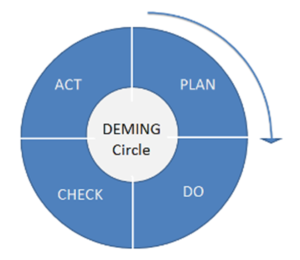

The Deming Cycle

This is often called Plan-Do-Check-Act (PDCA) although it’s also known as the Shewhart Cycle after Walter Shewhart, a physicist, engineer, and statistician.

This is often called Plan-Do-Check-Act (PDCA) although it’s also known as the Shewhart Cycle after Walter Shewhart, a physicist, engineer, and statistician.

The steps in this process are:

Plan – establish objectives, standards and processes to achieve the desired results

Do – carry out those processes

Check – check the work by gathering data and report findings to determine trends

Act – to address deviations from the standard, draw conclusions from the data, determine changes and implement those changes to standardise them.

14 points for success

In addition to the PDCA cycle, Deming created a set of guidelines for management to transform their business effectiveness. His 14 points for management as shown on the Deming Institute website are:

- Create constancy of purpose towards improvement of product and service. Aim to become competitive, to stay in business and provide jobs.

- Adopt the new philosophy. Management must awaken to the challenge, learn their responsibilities, and take on leadership for change.

- Cease dependence on inspection to achieve quality. Eliminate the need for inspection on a mass basis by building quality into the product in the first place. Use statistical evidence of process control along with incoming critical parts.

- End the practice of awarding business on the basis of price tag. Instead, minimise total cost. Move toward a single supplier for any one item on a long-term relationship built on loyalty and trust. Buy materials only if the supplier has a quality process.

- Improve constantly and forever the system of production and service, to improve quality and productivity, and thus constantly decrease costs.

-

Institute training on the job.

- Institute leadership. The aim of supervision should be to help people and machines and gadgets to do a better job.

- Drive out fear, so that everyone may work effectively for the company.

- Break down barriers between departments. People in research, design, sales, and production must work as a team.

- Eliminate slogans, exhortations, and targets for the work force asking for zero defects and new levels of productivity. This creates adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system.

- Review work standards to account for quality by (a) Eliminating work standards (quotas) on the factory floor and (b) Eliminating management by objective and numerical goals. Substitute leadership instead.

- (a) Remove barriers that rob the hourly worker of his right to pride of workmanship. The responsibility of supervisors must be changed from sheer numbers to quality. (b) Remove barriers that rob people in management and in engineering of their right to pride of workmanship.

- Institute a vigorous program of education and self-improvement

- Put everybody in the company to work to accomplish the transformation. The transformation is everybody’s job.

7 things to avoid

The same source also lists his 7 Deadly Diseases for Management:

- Lack of constancy of purpose to plan products and services that will have a market, keep the company in business, and provide jobs.

- Emphasis on short-term profits: short-term thinking. This is the opposite from constancy of purpose. It’s fed by fear of unfriendly takeover, and by the push for dividends.

- Evaluation of performance, merit rating, or annual review.

- Mobility of management; job hopping.

- Management by use only of visible figures, with little or no consideration of figures that are unknown or unknowable.

- Excessive medical costs.

- Excessive costs of liability, swelled by lawyers that work on contingency fees.

Joseph Moses Juran

“Observing many companies in action, I am unable to point to a single instance in which stunning results were gotten without the active and personal leadership of the upper managers”

Romanian born Dr Juran was a professor, engineer and consultant whose early work on statistical sampling and quality control techniques shaped the rest of his professional life. His philosophies also took root in Japan where his techniques became firmly embedded in that nation’s engineering and manufacturing industries.

He believed quality management must be across the whole organisation, from the highest management position to the least senior person in the business. His philosophy was influenced by the Pareto principle or the 80-20 rule, which states that for many events, 80% of the effects follow from 20% of the causes.

He focussed on the human dimension, emphasising the importance of training and education.

He focussed on the human dimension, emphasising the importance of training and education.

In his approach, the root cause of quality issues was often resistance to change and human relations challenges.

The quality trilogy

The Juran Quality Trilogy consists of the three processes making up the quality management journey. The components shown on the The Juran Institute website are:

Quality planning – This is effectively the design stage. The organisation establishes an understanding of its target customer’s needs, defines the features and specifications of the product or service, and devises the processes that will deliver on those needs.

Quality control – Ongoing quality control involves periodic checks and inspections and tracking metrics of critical elements to ensure the process is in control and meeting specifications. If defects are detected, implement a root cause analysis to enable corrective and preventative action.

Quality improvement – While organisations may expect to achieve incremental improvements by day-to-day means, breakthrough quality improvement involves the identification of areas where processes can be optimised, and the organised creation of beneficial change to attain measurably improved performance.

The Juran Model consists of five components which can lead to better business results and a culture of excellence:

- Understand the guiding principles that lay the foundation for excellence

- Improve the customer experience

- Create an infrastructure that engages employees to make improvements using the right methods and tools

- Use process improvement teams to drive process efficiency

- Ensure leadership and workforce engagement

The principles that underpin the Juran approach to improvement are to embrace quality and understand what it means to your customers.

However, the adoption of the Juran Trilogy must also take into account the Pareto Principle. You don’t have to improve everything. Focus on the vital issues preventing positive results.

Philip Bayard Crosby

“If we have delivered on time but the product has defects, we have not delivered on time”

Philip Crosby was an author, consultant and businessman who came to quality somewhat later than Deming and Juran.

His principle could be summed up simply – ‘Doing it Right the First Time’. This is expressed through his Absolutes of Quality Management and the Basic Elements of Improvement.

The Absolutes of Quality Management are:

- The First Absolute: The definition of quality is conformance to requirements

- The Second Absolute: The system of quality is prevention

- The Third Absolute: The performance standard is zero defects

- The Final Absolute: The measurement of quality is the price of nonconformance.

Crosby believed that his concept of Zero Defects should be an all-pervading philosophy that should influence every decision made. Management should reinforce this belief that defects are unacceptable and that closely monitoring details and avoiding errors is critical.

Crosby’s 14 steps to quality

Like Deming, Crosby had Fourteen Steps to Quality Improvement. However, his focus was somewhat different:

- Management commitment – make it clear that management is committed to quality

- Quality Improvement Teams formed with representatives from each department

- Measure quality of processes to determine where current and potential problems lie

- Assess the cost of quality and use it as a management tool for identifying where quality improvements could be profitably made

- Raise the quality awareness and personal commitment of all employees

- Correct problems identified through the previous steps

- Plan for zero defects by planning a zero defects program that fits the company and its culture

- Train all employees to actively carry out their part in the quality program

- Hold a Zero Defects Day to reaffirm commitment to the new direction

- Establish improvement goals for individuals and teams

- Remove obstacles and fear by encouraging employees to tell management about obstacles they face to improve quality

- Recognise and appreciate those employees who participate

- Establish Quality Councils to regularly communicate across the business, share experiences and generate ideas

- Repeat the cycle to demonstrate that quality improvement is a continuous process

And a quality vaccine!

Crosby also developed a ‘Quality Vaccine’, a preventative shot for businesses to prevent poor quality. The three parts of the vaccine are:

Integrity: quality must be taken seriously throughout the entire organisation. The company’s future will be judged by the quality it delivers.

Systems: the right measures and systems are needed for costs, performance, education, improvement, review and customer satisfaction.

Communication: through clear communication, the organisation will ensure everyone understands the specifications, requirements and improvement opportunities. Listening intently to customer and employee feedback and incorporating this will give any organisation the edge over its competitors.

So there you have it, three different views. Undoubtedly, we know that no single pathway will suit all business. But what do you think quality means? Perhaps you’ve adopted an approach that takes something from each. Or maybe you need help to find that elusive pathway.

Well, that’s what we’re here for! If you have any questions about your systems or processes, we’d love to help. Contact Maree on 0411 540 709 or email us info@masmanagementsystems.com.au

You don’t have to do this alone!

Download the article A trio of quality thinkers